Home>> Ball Bearing>>Ball Bearing >> Angular Contact Ball Bearings

Angular Contact Ball Bearings

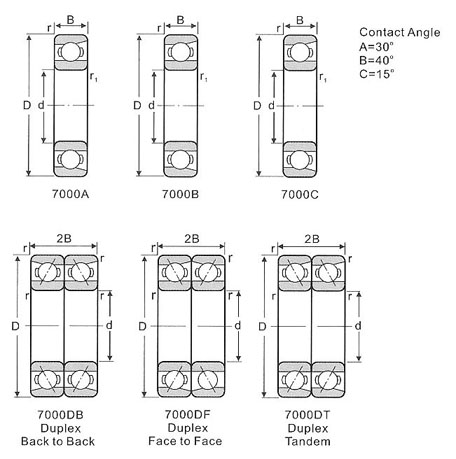

Angular Contact Ball Bearings is divided into angular contact ball bearings, double row angular contact ball bearings and four point contact ball bearings. It can bear radial and axial loads at the same time and can bear pure axial load as well with higher limiting speeds. The capability of bearing axial load is determined by the degree of contact angle. The bigger the contact angle is, and the bigger the axial load can be born. The bearings should be used in pair in general, in connection with installation in pairs, there are three kinds of ways, back to back, face to face and in series.

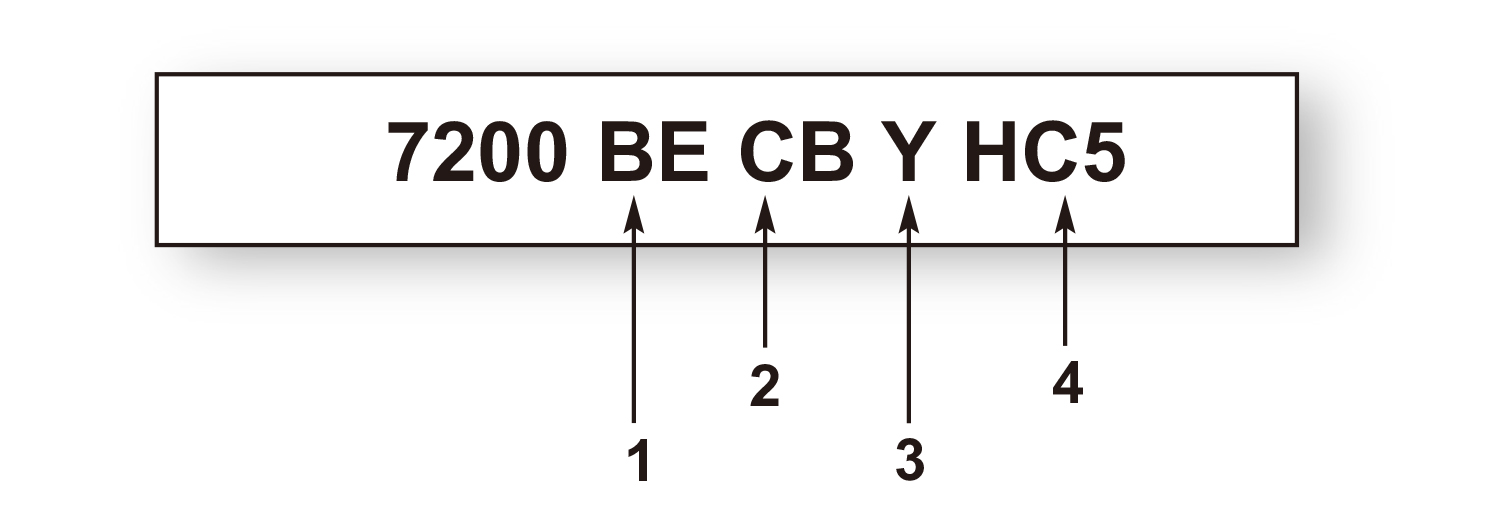

1. Design | 2. Clearance | 3. Cage Design | |||

A | Non-filling slot (Conrad type - | C2 | Axial clearance tighter | J | Pressed steel cage, ball |

3000, 5000 series) MRC. C. | than normal (3000,5000 | centred. | |||

B | 40° contact angle | and QJ series) | M | Machined brass cage, ball | |

BE | 40° contact angle, high | C3 | Axial clearance greater than | centred | |

capacity, all ISO corners | normal (3000, 5000 and QJ | P | Fibreglass reinforced | ||

D | Split inner ring (3300 series) | series) | polyamide,ball centred | ||

D | MRC 29° contact angle, 1/2 pair, | 7000 Series clearance* | Y | Press brass cage | |

duplex | CA | Modified for duplex mounting | 4. Special Features | ||

DU | MRC 29° contact angle and | with axial clearance < normal | HC4 | Full ceramic bearing | |

ground for duplex mounting and | CB | Modified for duplex mounting | HC5 | Ceramic ball set | |

zero preload/ clearance | with normal axial clearance | 5. Lubrication | |||

E | Filling slot (Max type - 5000 | CC | Modified for duplex mounting | MT33 | Medium temperature Lithium |

series) MRC. M. | with axial clearance >normal | grease, 74 cSt @ 40°C, | |||

FF | 2 Shields on MRC DRACBB | CN | Normal clearance (3000, 5000 | range -30°C to + 120°C | |

NR | Snap ring (3300,5000 series) | series) no symbol shown | GJN | Di-urea hi-temp, 115cSt | |

N2 | Locating slot (QJ Series) | GA | Modified for duplex mounting | @ 40°C, range -40°C to +150°C | |

R | MRC single row with 15° contact | with light preload | |||

angle | GB | Modified for duplex mounting | |||

RD | MRC single row for duplex | with medium preload | |||

mounting and 15° contact angle | GC | Modified for duplex mounting | |||

2RS1 | Rubber seals on both sides | with heavy preload | |||

ZZ | 2 rubber seals on MRC DRACBB | G… | Special preload, value in daN | ||

2Z | Metal shields on both sides | *If the above symbols from CA to G.. are | |||

(5000 series) | not shown the bearing is not modified for | ||||

duplex mounting | |||||